Product flow through manufacturing is the determinant of efficiency

It sets manufacturing cycle time and Work-in-Process.

Our inter process material handling gains 30% in cycle time over discrete Work-in-Process transports through autonomous, collision less, soft accumulating workflow.

Examples:

Replacing or augmenting

over head vehicle lines

or guided vehicles

Our Inter Process Material Handling improves:

- Manufacturing Cycle Time (CT)

- Throughput Capacity (CY)

- Inter Process Delivery (T)

- Work in Process Content (W)

- And Over all Costs (C)

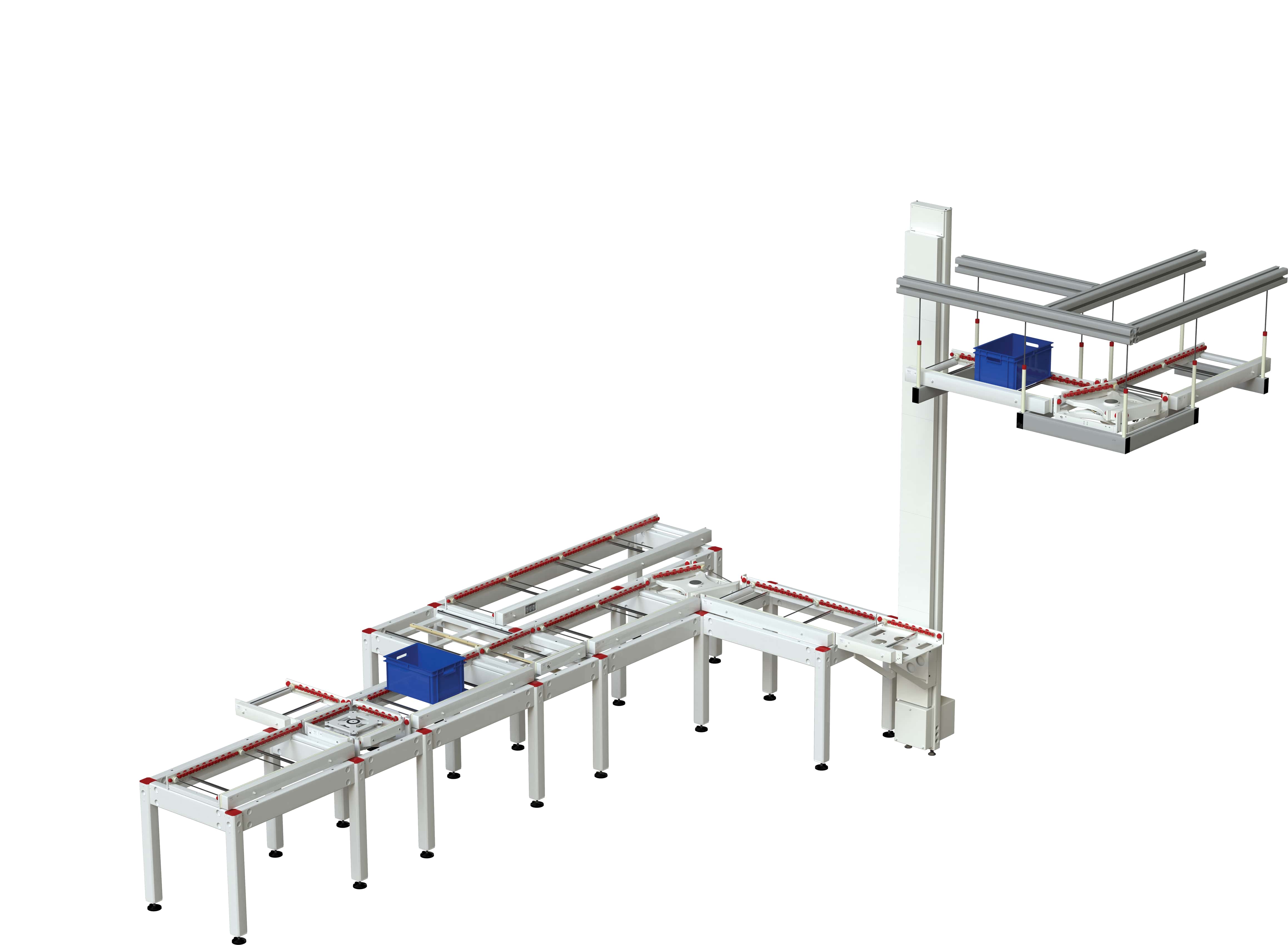

Via direct, independent work flow on single conveyor lines or conveyor networks

Typical Areas of Application:

- In factories with manual material handling

- As add on to existing production lines and factories with discrete vehicle material transports

- In new factories as standalone conveyor transports

- In new factories to parallel the discrete vehicle transports with conveyors

Our 50 years of experience includes industries as:

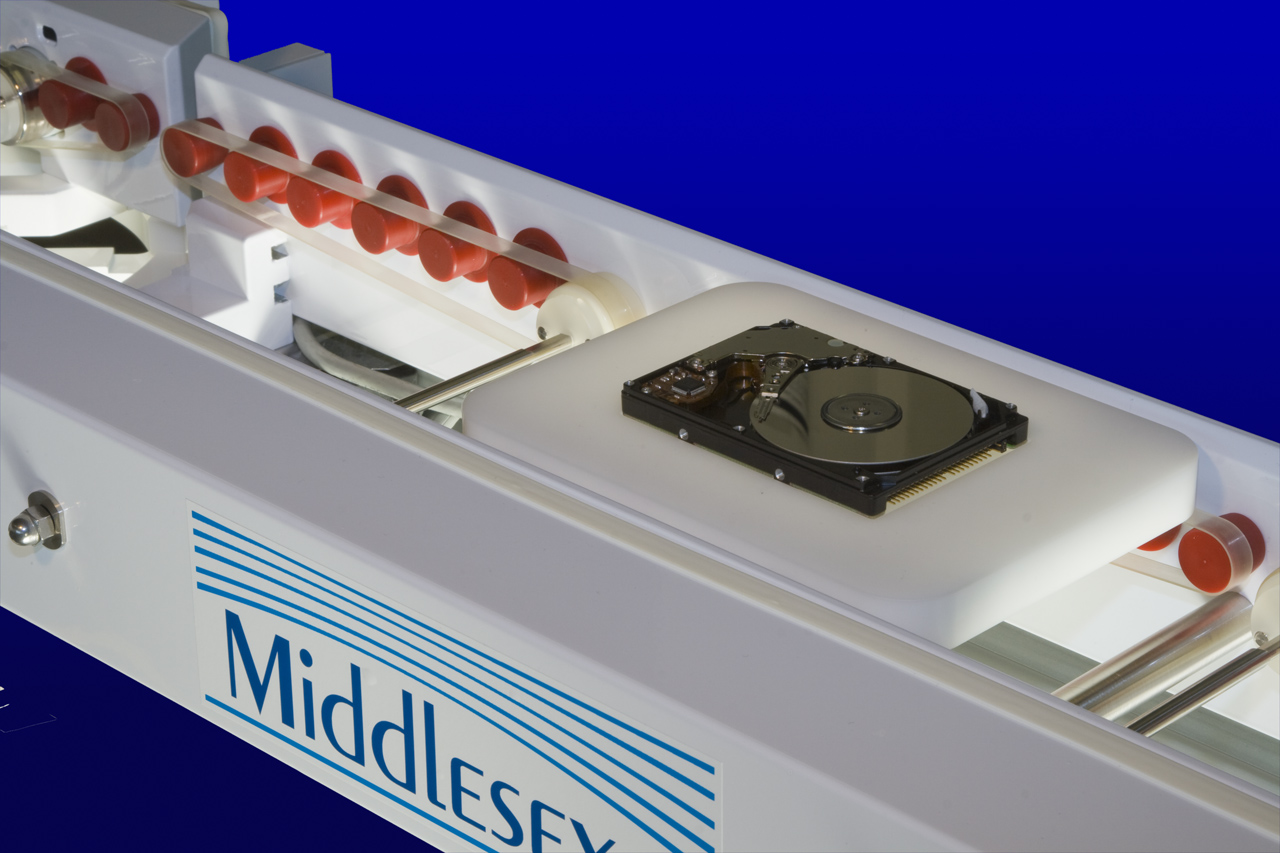

- Semiconductors

- Data storage media manufacturing

- Pharma

- Medical devices

- Chemical industry (bulk materials)

- Automated assembly

- Order sort/Warehouse

OUR SUPER (ROBOTIC) CONVEYORS:

Are capable of transferring, accumulating, and storing a product as individual independent products with independent destinations without interference. Configuring such super conveyors into a network achieves unprecedented productivity gains.

WHAT A SUPERCONVEYOR IS NOT:

Such a conveyor is not really a conveyor in the common sense.

Product Configurations:

- Rectilinear track layout with standard linear module sizes, turning/crossing modules, and elevation modules.

- Ceiling mount or floor mount tracks.

- Mechanical and controls interface with industry standards.

- ISO 3 particle cleanliness operation

- Static free and low vibrations WIP moves

- Transport modules width by the company (to accommodate the customer’s product carrier)

- Product carrier speed settings

- Factory host interface settings

Product Specifications:

- Super Conveyor Module (with embedded controls): 0.5, 1.0, 1.5, 2 m

- Transport Speed settings: up to 1.2 m/sec

- Clean room compliance: ISO 3

- Vibrations: 0.3g RMS

- Electro statics: dissipating class

- Controls: embedded with factory host and interface to GUI