Welcome to

Middlesex Industries

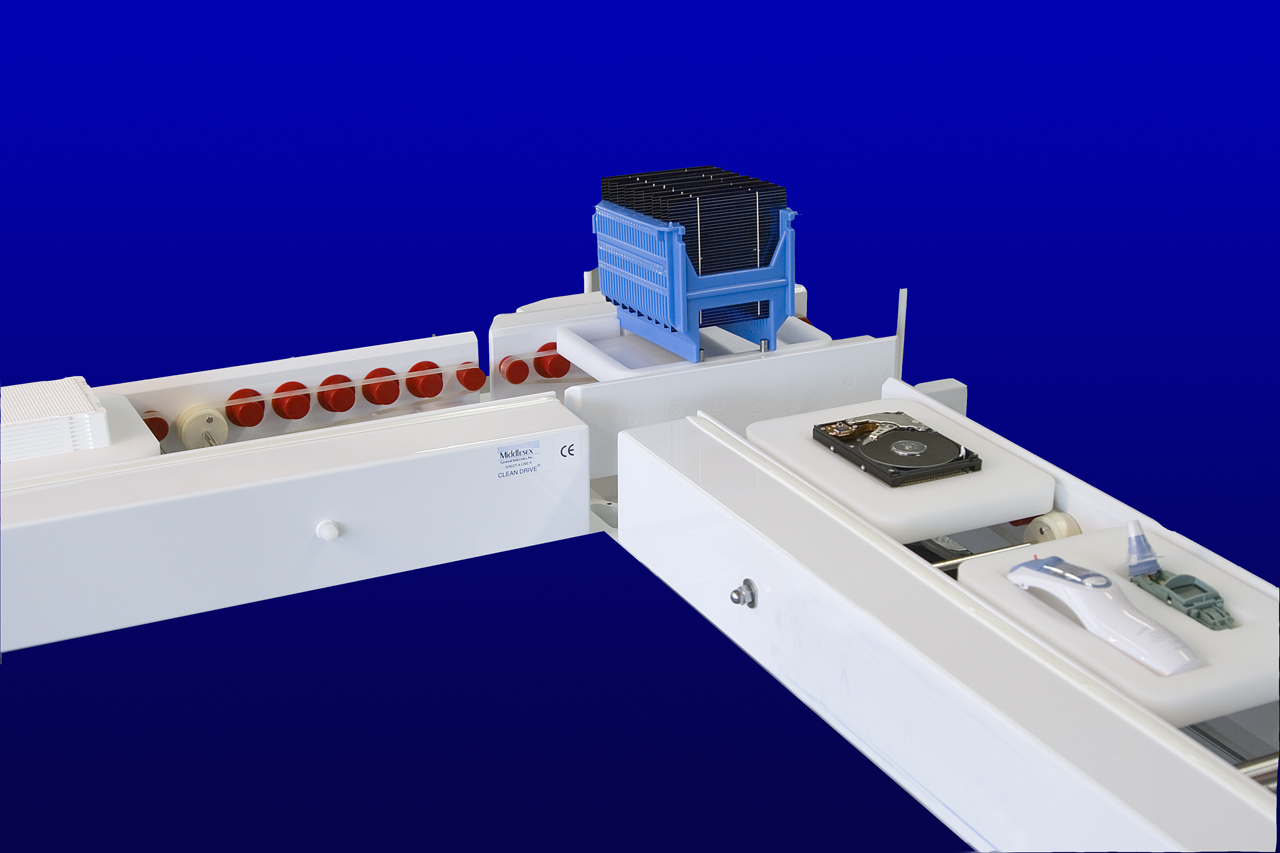

Pioneering Manufacturing Automation Since 1968

Middlesex Industries delivers productivity improvements in manufacturing logistics through revolutionized conveyor concepts.

Our systems are designed to surpass the limitations of traditional discrete material handling by enabling a continuous inter process production flow.

We focus on specialized solutions for:

With advanced facilities in the Eastern United States and Southern Switzerland, we support clients worldwide with high-performance automation systems.

Conveyors for LEAN MANUFACTURING:

Discover how our next-generation conveyor technologies help drive efficiency, reliability, and precision in LEAN MANUFACTURING environments.